搞懂FFU,轻松搞定洁净室空气控制(中英文)

1. 什么是风机过滤单元(FFU)?

What is a Fan Filter Unit (FFU)?

风机过滤单元(FFU)是一种独立的空气过滤风机系统,包括:

高效HEPA/ULPA过滤器,用于去除颗粒物

集成式风机、过滤器和电机,用于维持气流

层流控制,营造洁净环境

适用于FFU洁净室、实验室和制药生产区域

过滤风机可补偿压降(空气通过过滤单元时产生的阻力),确保气流稳定。

A fan filter unit(ffu) is a self-contained air filtration fan system that includes:

High-efficiency HEPA/ULPA filters for particle removal

An integrated fan and filter unit & motor to maintain airflow

Laminar airflow control for clean environments

Used in ffu clean room , laboratories, and pharmaceutical production areas

The filter fan compensates for pressure drop(The resistance generated as air passes through the filter unit), ensuring consistent airflow.

2. 风机过滤单元(FFU)的工作原理是什么?

How Does a Fan Filter Unit (FFU) Work?

风机过滤器单元(FFU)从设备的顶部或背面吸入环境空气,使其通过HEPA风机过滤器单元或ULPA过滤器,然后将过滤后的空气以均匀层流的形式输送到受控空间。

工作流程包括以下步骤:

- 进气 – 过滤风机单元从周围环境或管道系统中吸入未经过滤的空气。

- 过滤 – 空气依次通过高效空气微粒过滤器(HEPA,对 0.3 微米颗粒的过滤效率为 99.99%)或超高效空气微粒过滤器(ULPA,对 0.12 微米颗粒的过滤效率为 99.9995%),去除空气中的污染物。

- 空气分配 – 过滤后的空气以可控的层流方式排出,最大限度地减少湍流,降低污染风险。

- 静压调节 – 集成式风机过滤器电机维持适当的静压,以补偿随着颗粒物积累而增加的过滤阻力。

A fan filter unit ffu draws in ambient air from the top or back of the unit, passes it through a hepa fan filter unit or ULPA filter, and then supplies the filtered air into the controlled space in a uniform laminar flow.

The working process includes the following steps:

- Air Intake – The filter fan unit pulls in unfiltered air from the surrounding environment or a ducted system.

- Filtration – The air passes through a hepa filter for fan (99.99% efficiency at 0.3 microns) or ULPA filter (99.9995% efficiency at 0.12 microns), removing airborne contaminants.

- Air Distribution – The filtered air is discharged in a controlled, laminar flow, minimizing turbulence and reducing contamination risks.

- Static Pressure Adjustment – The integrated fan filter motor maintains proper static pressure to compensate for increasing filter resistance as particles accumulate over time.

3. 风机过滤单元(FFU)有哪些有点?

What are the Advantages of a Fan Filter Unit (FFU)?

根据行业研究,使用配备高效空气微粒过滤器(HEPA)的风机过滤单元(FFU)的洁净室可实现高达 99.99% 的颗粒物去除效率,显著改善空气质量,并降低制药和半导体环境中的污染风险。

风机过滤单元在洁净室和暖通空调(HVAC)系统中的主要优势:

- 高效过滤 – 配备HEPA或ULPA过滤器的风机过滤单元(FFU)可有效去除空气中的污染物,例如灰尘、细菌和气溶胶颗粒。

- 稳定的气流控制 – 内置风机可确保稳定的气流,即使过滤器随着时间的推移积累颗粒物。

- 节能 – 与传统电机相比,采用电子换向电机(ECM)的型号可显著节省能源。

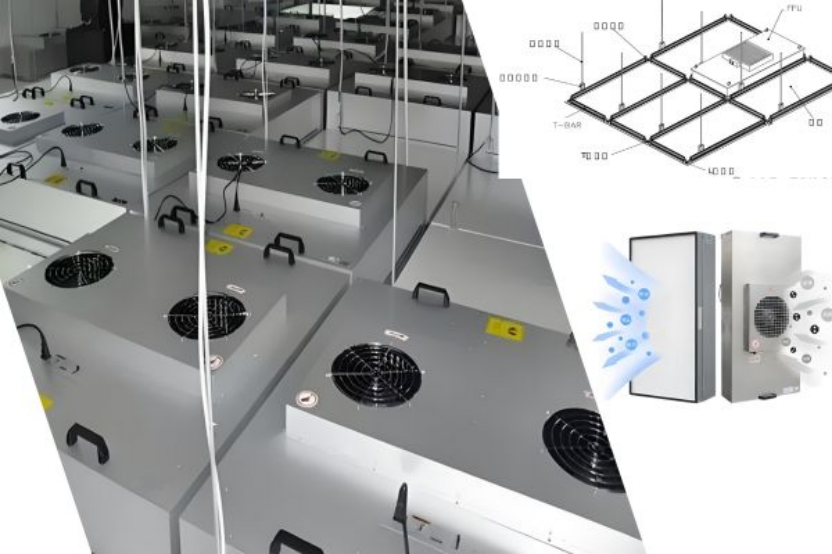

- 模块化和可扩展性 – 用于洁净室安装的风机过滤单元(FFU)可无缝集成到天花板龙骨中,也可轻松添加到现有的暖通空调(HVAC)系统中,使其能够灵活应用于各种场合。

- 静音运行 – 与大型集中式空气处理系统相比,FFU的运行噪音更低,是实验室和洁净室环境的理想之选。

- 更高的换气率 – FFU有助于维持高换气率(每小时换气次数),这对于洁净室和制药环境至关重要。

According to industry studies, cleanrooms using HEPA-equipped FFU can achieve up to 99.99% particle removal efficiency, significantly improving air quality and reducing contamination risks in pharmaceutical and semiconductor environments.

Key Benefits of fan filters in Cleanrooms and HVAC Systems:

- High Filtration Efficiency – Equipped with HEPA or ULPA filters, FFU effectively remove airborne contaminants such as dust, bacteria, and aerosolized particles.

- Consistent Airflow Control – The built-in fan ensures stable airflow, even as the filter loads with particles over time.

- Energy Efficiency – Models with electronically commutated motors (ECM) provide significant energy savings compared to traditional motors.

- Modular and Scalable – Fan filter unit for clean room installations integrate seamlessly into ceiling grids, also can be easily added to existing HVAC systems , making them flexible for various applications.

- Quiet Operation – Compared to large centralized air handling systems, FFU operate at lower noise levels, Ideal for labs and ffu clean room environments.

- Improved Air Change Rates – FFU contribute to maintaining high air change rates(Air changes per hour), a critical requirement in cleanroom and pharmaceutical environments.

4. FFU的结构是什么?

What is the Structure of an FFU?

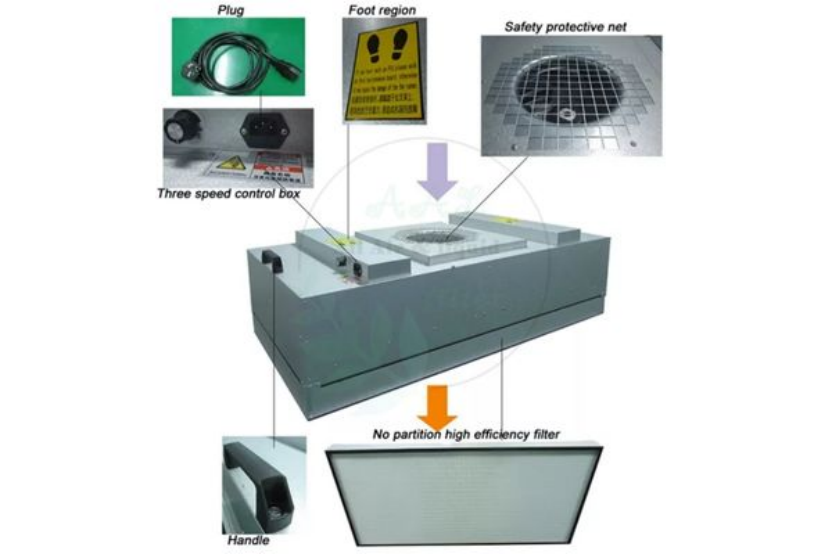

风机过滤装置由以下几个关键部件组成:

- 外壳 – 由铝、不锈钢或粉末涂层钢制成,外壳包裹着过滤风机和电机。

- 风机和电机组件 – 驱动空气流经过滤器,可选永磁分相电容式(PSC)电机或电子换向电机(ECM)版本。

- HEPA/ULPA 过滤器 – 核心过滤单元,用于在气流进入受控环境之前去除其中的颗粒污染物。

- 控制系统 – 部分高级型号配备可调速控制、气流传感器和风机过滤装置的远程监控功能。

- 进气和分配系统 – 旨在保持均匀的气流,最大限度地减少湍流(湍流可能导致污染物扩散)和污染风险。

A fan filter unit consists of several key components:

- Housing – Made of aluminum, stainless steel, or powder-coated steel, the housing encloses the filter fan and motor.

- Fan and Motor Assembly – Drives air through the filter, available in either Permanent Split Capacitor (PSC) or Electronically Commutated Motor (ECM) versions.

- HEPA/ULPA Filter – Core filter unit for Remove particulate contaminants from the airflow before it enters the controlled environment.

- Control System – Some advanced models feature adjustable speed control, airflow sensors, and remote monitoring capabilities for fan filter.

- Air Intake and Distribution System – Designed to maintain uniform airflow, minimizing turbulence(Turbulence may lead to the dispersion of contaminants) and contamination risks.

5. 为什么需要使用风机过滤单元(FFU)?

Why Do You Need to Use a Fan Filter Unit (FFU)?

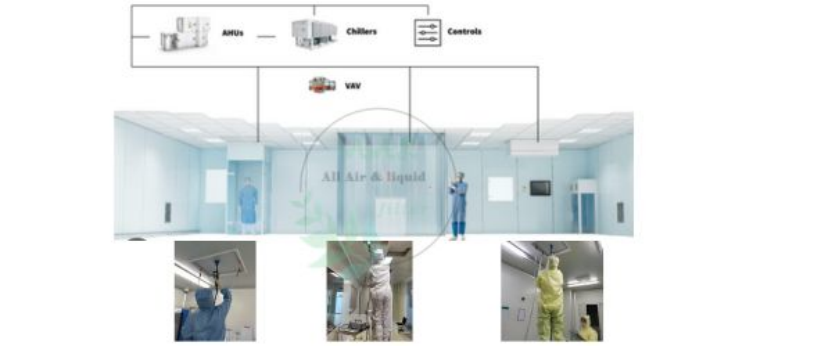

在对空气洁净度和控制要求极高的环境中,风机过滤单元(FFU)至关重要。它们广泛应用于:

- 洁净室和受控环境 – 半导体制造、制药和生物技术行业防止污染的必备设备。

- 医疗保健设施 – 医院药房、药品配制区和手术室使用高效空气微粒过滤器(HEPA)风机来维持无菌环境。

- 食品饮料行业 – 洁净室风机过滤单元可防止食品加工和包装区域的空气污染。

- 航空航天和微电子制造 – 保护敏感元件免受空气颗粒物和静电放电的损害。

- 暖通空调和实验室应用 – 为现有暖通空调系统和实验室工作站提供辅助空气过滤。

FFU are essential in environments where high levels of air cleanliness and control are required. They are widely used in:

- Cleanrooms and Controlled Environments – Essential for semiconductor manufacturing, pharmaceuticals, and biotechnology to prevent contamination.

- Medical and Healthcare Facilities – HEPA filter fans Used in hospital pharmacies, pharmaceutical compounding areas, and surgical rooms to maintain sterile conditions.

- Food and Beverage Industry – Fan filter unit for clean room to prevent airborne contamination in food processing and packaging areas

- Aerospace and Microelectronics Manufacturing – Protects sensitive components from airborne particles and electrostatic discharge.

- HVAC and Laboratory Applications – Provides supplementary air filtration in existing HVAC systems and laboratory workstations.

6. 如何选择合适的风机过滤单元(FFU)?

How to Choose the Right Fan Filter Unit (FFU)?

选择FFU时,请考虑以下因素:

(1)应用要求 – 根据洁净度标准,确定需要的是高效空气微粒过滤器(HEPA)还是超高效空气微粒过滤器(ULPA)。

风机过滤单元(FFU)可配备:

- HEPA过滤器:对小至0.3微米的颗粒物捕获效率高达99.99%。

- ULPA过滤器:对小至0.12微米的颗粒物捕获效率高达99.9995%,适用于超洁净应用。

(2)尺寸和风量 – 选择适合天花板龙骨并提供所需风量的尺寸。

风机过滤单元通常有三种标准尺寸:

- 2 英尺 x 4 英尺(最常用,标准风速下风量为480 CFM)

- 2 英尺 x 2 英尺

- 4 英尺 x 4 英尺

(3)电机类型 – 如果能效是首要考虑因素,请选择ECM电机而不是PSC电机。 电机是FFU的关键部件,对能源效率和运行成本有着显著影响。

主要有两种类型的电机:

- 永磁分相电容式(PSC)电机:传统交流感应电机,初始成本较低,但能效较低,运行速度固定。

- 电子换向电机(ECM):无刷直流电机,内置微处理器,性能优化,效率更高,能耗更低。虽然初始成本较高,但节能效果显著,通常在第一年即可收回成本。

(4) 过滤器更换方式 – 如果预计需要频繁维护,则室内可更换式(RSR)装置可能更方便。

主要有两种更换方式:

- 室内可更换式(RSR)装置:采用集成刀口设计,可与凝胶密封过滤器啮合,防止空气旁通。无需拆卸天花板或周围结构,即可在室内更换过滤器。

- 台式可更换单元:更换过滤器时需要将设备从天花板上拆下。其过滤面积比RSR单元大 25%,从而实现更高的风量和更长的过滤器寿命。

(5)气流控制需求 – 根据系统的压力控制要求,选择恒扭矩或恒流量电机程序。

FFU 可根据应用需求配置不同的气流模式:

- 送风(最常用):空气从设备的背面/顶部(通过风管连接或非风管静压箱)吸入,并以层流向下输送。适用于洁净室、制药环境和微电子制造。

- 排风/逆流:空气从设备的穿孔面吸入,经过过滤后排出到受控空间外或循环利用。适用于需要将空气污染物从房间中移除而不是引入的应用。

(6)预算和生命周期成本——虽然ECM电机和ULPA过滤器的初始成本较高,但它们在能源效率和改善空气质量方面提供了长期的节省。

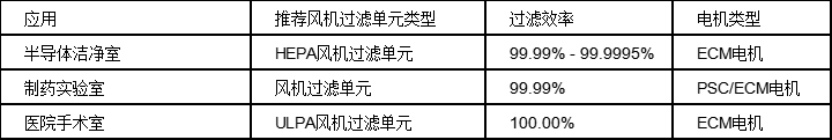

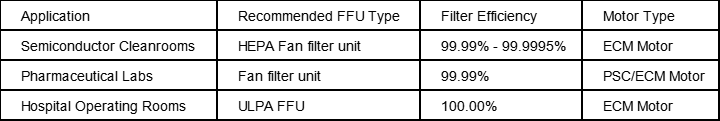

(7)根据应用选择最佳FFU类型

When selecting an FFU, consider the following factors:

(1) Application Requirements – Determine whether you need HEPA filter for fan or ULPA filters based on cleanliness standards.

FFU can be equipped with:

- HEPA Filters: 99.99% efficiency at capturing particles as small as 0.3 microns.

- ULPA Filters: 99.9995% efficiency at capturing particles as small as 0.12 microns, suitable for ultra-clean applications.

(2) Size & Airflow Capacity – Choose a size that fits your ceiling grid and provides the necessary airflow.

Fan filter unit are typically available in three standard sizes:

- 2 ft. x 4 ft. (Most common, provides 480 CFM at standard velocity)

- 2 ft. x 2 ft.

- 4 ft. x 4 ft.

(3) Motor Type – If energy efficiency is a priority, opt for ECM motors instead of PSC motors.

The motor is a key component of FFU, impacting energy efficiency and operational costs.

Two primary motor types are used:

- Permanent Split Capacitor (PSC) Motors Traditiona- AC induction motors Lower initial cost but less energy efficient Fixed-speed operation

- Electronically Commutated Motors (ECM) Brushless DC motors with onboard microprocessors for optimized performance Higher efficiency, reducing energy consumption The initial higher cost is offset by energy savings, typically recovering costs within the first year.

(4) Filter Replacement Method – If frequent maintenance is expected, room-side replaceable (RSR) units may be more convenient.

There are two primary replacement options:

- Room-Side Replaceable (RSR) Units: Feature an integrated knife-edge that engages with the gel-seal filter, preventing air bypass. Allows filter replacement from within the room without disturbing the ceiling or surrounding structure.

- Benchtop Replaceable Units: Require the unit to be removed from the ceiling for filter changes.Have 25% more filter area than RSR units, enabling higher airflow rates and extended filter life.

(5) Airflow Control Needs – Decide between constant torque or constant flow motor programs based on your system’s pressure control requirements.

FFU can be configured for different airflow patterns based on application requirements:

- Supply Flow (Most Common) Air is drawn in through the back/top of the unit (from a ducted connection or non-ducted plenum) and supplied downward with laminar airflow. Used in cleanrooms, pharmaceutical environments, and microelectronics manufacturing.

- Exhaust/Reverse Flow Air is pulled in through the perforated face of the unit and filtered before being exhausted outside the controlled space or recirculated. Used in applications where airborne contaminants need to be removed from a room rather than introduced.

(6) Budget & Lifecycle Costs – While ECM motors and ULPA filters have higher initial costs, they offer long-term savings in energy efficiency and improved air quality.

(7) Best FFU Type Based on Application

7. 关于风机过滤单元(FFU)的常见问题解答(FAQ)

Frequently Asked Questions (FAQ) About Fan Filter Units (FFU)

洁净室需要多少台风机过滤单元(FFU)?

所需的风机过滤单元数量取决于洁净室的面积和每小时换气次数(ACH):

ISO 5 级洁净室(100级)– 约500-750次/小时

ISO 7 级洁净室(10,000级)– 约60-90次/小时

ISO 8 级洁净室(100,000级)– 约15-25次/小时

How many FFUs do I need for my cleanroom?

The number of FFUs needed depends on the cleanroom size and required air changes per hour (ACH):

ISO 5 Cleanroom (Class 100) – ~500-750 ACH

ISO 7 Cleanroom (Class 10,000) – ~60-90 ACH

ISO 8 Cleanroom (Class 100,000) – ~15-25 ACH

风机过滤单元(FFU)需要特殊维护吗?

风机过滤单元(FFU)的常规维护包括:

每 3-6 个月清洁一次预过滤器

每 1-3 年更换一次风机的 HEPA 过滤器(取决于使用情况)

每年检查风机和电机的运行情况,以确保其性能

Do FFU require special maintenance?

Regular maintenance for fan filter includes:

Cleaning the pre-filters every 3-6 months

Replacing HEPA filter for fan every 1-3 years (depending on usage)

Inspecting fan & motor operation annually to ensure performance

风机过滤单元(FFU)可以在负压环境中运行吗?

是的,风机过滤单元(FFU)可以在需要控制空气污染物的负压房间中运行,例如生物安全实验室和隔离室。

Can FFU operate in negative pressure environments?

Yes, FFU can function in negative pressure rooms where airborne contaminants need to be contained, such as biosafety labs and isolation rooms.

风机过滤单元(FFU)的风速是多少?

FFU 的标准风速为每分钟 90-100 英尺(FPM),确保层流气流,从而有效控制污染。

What is the airflow velocity of an FFU?

The standard air velocity of an FFU is 90-100 feet per minute (FPM), ensuring laminar airflow for contamination control.

可以在现有的暖通空调(HVAC)系统中安装FFU吗?

可以,风机过滤单元可以集成到现有的HVAC系统中,也可以作为独立的过滤单元使用。它们可以安装在吊顶、洁净室格栅或层流工作站中。

Can I install an FFU in an existing HVAC system?

Yes, fan filter unit can be integrated into existing HVAC systems or used as standalone filtration units. They can be mounted in suspended ceilings, cleanroom grids, or laminar flow workstations.

FFU节能吗?

是的,尤其是配备电子换向电机(ECM)的FFU型号,其能耗比传统电机低30-50%。

Are FFU energy efficient?

Yes, especially ffu models with Electronically Commutated Motors (ECM), which consume 30-50% less energy than traditional motors.

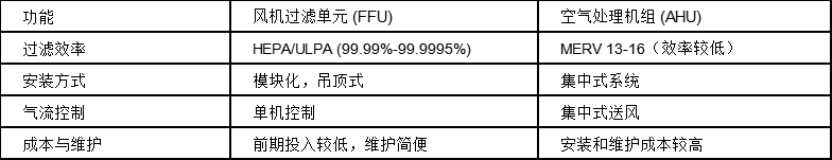

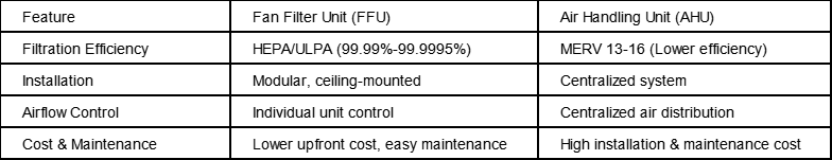

FFU和传统空气处理机组(AHU)有什么区别?

What is the difference between an FFU and a traditional air handling unit (AHU)?

FFU的预期寿命是多久?

如果维护得当,FFU设备可以使用10年以上,但过滤器需要根据环境条件每1-3年更换一次。

What is the expected lifespan of an FFU?

With proper maintenance, an FFU unit can last 10+ years, though the filters need replacement every 1-3 years depending on environmental conditions.

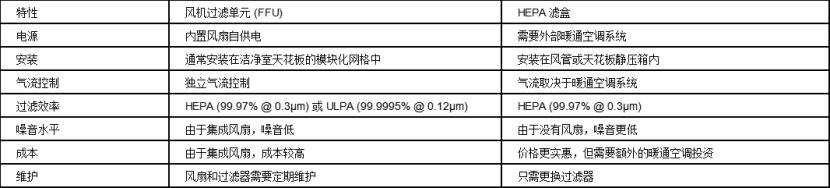

什么是 HEPA 空气净化箱?

HEPA空气净化箱,也称为末端HEPA过滤单元,是一种简单的空气过滤设备,由HEPA过滤器、扩散器和进气口组成。与风机单元(FFU)不同,HEPA 空气净化箱没有内置风机;它依靠外部HVAC系统将空气输送通过过滤器。

What is a HEPA Box?

A HEPA Box, also known as a terminal HEPA filter unit, is a simple air filtration device that consists of a HEPA filter, a diffuser, and an air inlet. Unlike FFUs, HEPA Boxes do not have built-in fans; instead, they rely on an external HVAC system to deliver air through the filter.

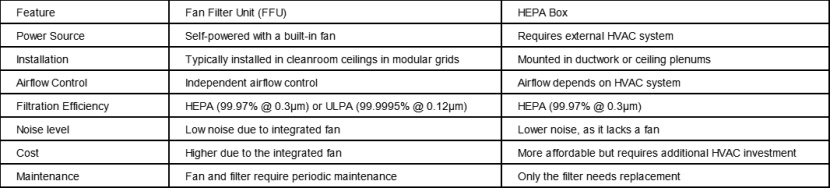

风机过滤单元(FFU)和HEPA空气净化箱的区别

Differences Between FFU and HEPA Box

声明:

-文章转载自AALFILTER,由爱泽工业翻译,如有侵权,请联系删除!

-如有偏颇,欢迎指正!

沪公网安备31011002006738号

沪公网安备31011002006738号