FFU风机过滤单元的布局如何影响颗粒计数和ISO认证(中英文)

在设计洁净室时,要达到相应的ISO等级,不仅仅取决于选择合适的风机过滤单元,风机过滤单元(FFU)的安装方式和位置也很重要。FFU的布局直接影响颗粒物浓度、气流模式,并最终影响洁净室是否符合ISO标准。

本文将探讨FFU的布局如何影响洁净室的性能,常见的FFU设计错误,以及满足ISO认证要求的最佳实践。

When designing a cleanroom, achieving the appropriate ISO classification depends on more than just choosing the right fan filter. It also depends heavily on how and where fan filter units (FFUs) are placed. FFU layout directly affects particle count, airflow patterns, and ultimately, the cleanroom’s compliance with ISO standards.

Here, we will explore how FFU placement contributes to cleanroom performance, the common design mistakes people make, and the best practices for meeting ISO certification requirements.

为什么过滤单元(FFU)的放置很重要

Why FFU Placement Matters

空气过滤单元(FFU)提供局部过滤气流,以去除空气中的颗粒物并维持洁净度标准。然而,其有效性不仅取决于过滤器类型(HEPA 与 ULPA),还取决于气流动力学、覆盖面积和房间布局。

FFU放置不当可能导致:

• 空气流动死角,污染物在此积聚

• 湍流气流模式会搅动颗粒物而不是将其清除

• 压力分布不均,导致不符合ISO标准

• 过滤过度或过滤不足的区域,尤其是在墙壁或设备附近

即使在过滤能力充足的洁净室中,FFU布局不当也会影响空气洁净度,并增加ISO认证测试不合格的风险。

FFUs provide localized, filtered airflow to remove airborne particles and maintain cleanliness standards. However, their effectiveness depends not only on filter type (HEPA vs. ULPA) but also on airflow dynamics, coverage area, and room layout.

Improper FFU placement can lead to:

• Airflow dead zones where contaminants accumulate

• Turbulent air patterns that stir up particles instead of removing them

• Uneven pressure distribution, leading to ISO noncompliance

• Over- or under-filtered zones, especially near walls or equipment

Even in a cleanroom with sufficient filtration capacity, poor FFU layout can compromise air cleanliness and increase the risk of failing ISO certification testing.

颗粒计数与ISO标准之间的联系

The Link Between Particle Count and ISO Standards

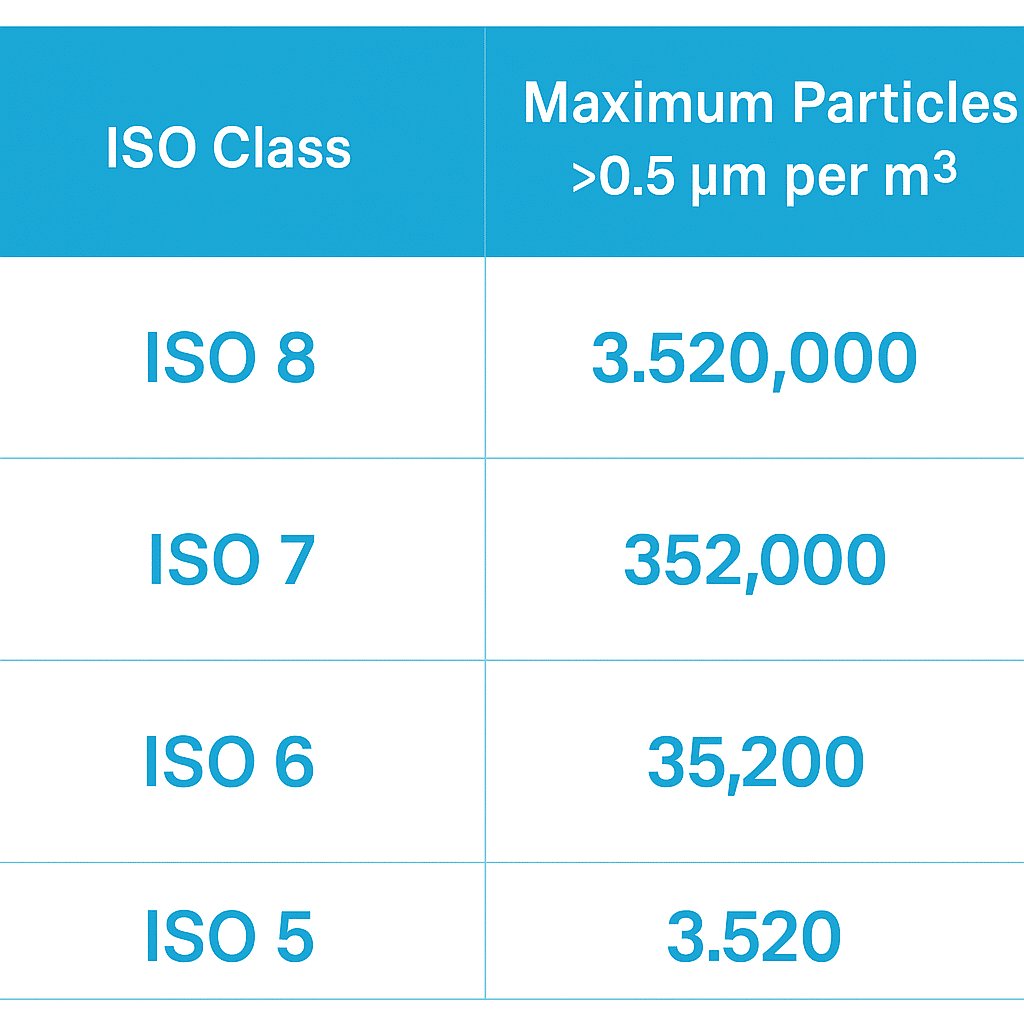

ISO 14644-1根据每立方米允许的颗粒计数定义了洁净室等级。例如:

ISO 14644-1 defines cleanroom classifications based on allowable particle counts per cubic meter. For example:

为维持这些洁净度,FFU必须产生稳定的层流,将空气中的颗粒向下吹扫并排出洁净区。合理的布置可确保:

• 全面覆盖关键工艺区域

• 无颗粒回流或滞留

• 与相邻空间保持适当的压力

To maintain these levels, FFUs must generate a consistent laminar airflow that sweeps airborne particles downward and out of the clean zone. Strategic placement ensures:

• Full coverage of critical process areas

• No recirculation or stagnation of particles

• Proper pressurization relative to adjacent spaces

FFU安置的关键因素

Key Factors in FFU Placement

1. 覆盖范围

Coverage Area

风机过滤单元(FFU)的间距应确保洁净室天花板上气流覆盖均匀且相互重叠。一般而言,ISO 7-8级洁净室每6英尺 × 6 英尺至 8 英尺 × 8 英尺可安装一个 FFU,而ISO 5-6级洁净室则需要更高的覆盖密度,通常需要部分或全部覆盖天花板。最终的间距应始终根据风量、每小时换气次数(ACH)和房间几何形状进行验证。

Fan Filter Units (FFUs) should be spaced to provide consistent and overlapping airflow coverage across the cleanroom ceiling. As a general guideline, one FFU per approximately 6 ft × 6 ft to 8 ft × 8 ft can be used for ISO 7–8 cleanrooms, while higher-density coverage is required for ISO 5–6 environments, often approaching partial or full ceiling coverage. Final spacing should always be validated based on airflow volume, air changes per hour (ACH), and room geometry.

2. 气流方向和位置

Airflow Direction and Placement

FFU(风机盘管)通常安装在关键工作区域上方的天花板上,以提供垂直向下的气流。这有助于形成洁净的气流模式,并最大限度地减少使用点的颗粒物积聚。FFU 的安装位置应避开墙壁、照明或其他可能阻碍气流的障碍物。虽然 ISO 5 级洁净室通常需要真正的单向(层流)气流,但如果平衡得当,天花板安装的 FFU 也能在 ISO 7-8 级洁净室中实现有效的气流分布。

FFUs are typically installed in the ceiling above critical work areas to deliver vertical, downward airflow. This supports clean airflow patterns and helps minimize particle accumulation at the point of use. Units should be positioned to avoid walls, lighting, or other obstructions that could disrupt airflow. While true unidirectional (laminar) flow is generally required for ISO 5 environments, ceiling-mounted FFUs also support effective airflow distribution in ISO 7–8 cleanrooms when properly balanced.

3. 工艺区

Process Zones

洁净室布局应考虑空间内不同的洁净度要求。关键工艺区域,例如装配区、灌装区或检验区,通常需要更高的空气流转单元(FFU)密度和气流。而洁净度较低的区域,包括更衣室、走廊和辅助空间,则可以使用较少的空气流控单元,但仍能保持适当的洁净度水平。

Cleanroom layouts should account for different cleanliness requirements within the space. Critical process areas, such as assembly, filling, or inspection zones, typically require higher FFU density and airflow. Lower-class areas, including gowning rooms, corridors, and support spaces, can operate with fewer FFUs while still maintaining appropriate cleanliness levels.

4. 加压

Pressurization

风机盘管单元(FFU)的布局和风量必须能够维持相邻空间之间适当的压差。高等级洁净室应保持相对于低等级区域的正压,以防止污染物进入。例如,与ISO 8洁净室相邻的ISO 7洁净室通常需要更高的风量和换气次数(ACH)来维持这种压差。压力是通过适当的送风和回风或排风之间的空气平衡来实现的,而不仅仅是风机盘管单元(FFU)本身。

FFU layout and airflow volume must support proper pressure differentials between adjacent spaces. Higher-class cleanrooms should maintain positive pressure relative to lower-class areas to prevent contamination ingress. For example, an ISO 7 cleanroom adjacent to an ISO 8 space will typically require higher airflow and ACH to sustain this pressure gradient. Pressurization is achieved through proper air balance between supply and return or exhaust air, not FFUs alone.

避免常见的FFU放置错误

Common FFU Placement Mistakes to Avoid

• 角落或墙边FFU数量不足,导致颗粒物积聚

• 将FFU直接放置在高温设备上方,可能导致湍流

• 未考虑工艺过程中产生的颗粒物,尤其是在生产制造过程中产生的颗粒

• 间距不均匀,导致某些区域空气停滞或过度过滤

• Insufficient FFUs in corners or along walls, leading to particle buildup

• Placing FFUs directly above high-heat equipment, which may cause turbulence

• Not accounting for process-generated particles, especially in manufacturing

• Uneven spacing, which results in air stagnation or over-filtration in areas

室内可更换式FFU提升维护效率和合规性

Roomside Replaceable FFUs Improve Maintenance and Compliance

对于注重长期性能和便捷维护的组织而言,室内可更换式风机过滤单元(FFU)具有显著优势。这些单元可在洁净室内进行维护,最大限度地减少停机时间,并避免拆卸密封件或进入送风静压箱。这使得在不影响洁净度的前提下,更容易维持适当的气流和颗粒物浓度。

在需要频繁验证和更换过滤器的ISO 5-6级洁净环境中,可从洁净室内部更换FFU尤为重要。

For organizations focused on long-term performance and easy maintenance, roomside replaceable FFUs offer a significant advantage. These units can be accessed and serviced from inside the cleanroom, minimizing downtime and eliminating the need to break seals or enter plenum spaces. This makes it easier to maintain proper airflow and particle counts without compromising cleanliness.

Roomside replaceables are especially valuable in ISO 5–6 environments, where frequent validation and filter replacement are necessary.

设计FFU布局时,请考虑ISO合规性

Design Your FFU Layout with ISO Compliance in Mind

洁净室认证不仅仅关乎使用哪些组件,更关乎如何使用它们。FFU的合理布局对于降低颗粒计数和达到ISO合规性至关重要。无论是设计新的洁净室还是升级现有洁净室,了解气流动力学都能帮助避免合规性问题、提高运营效率并保护产品和工艺。

Cleanroom certification isn’t just about what components you use, it’s about how you use them. Proper FFU placement is critical to reducing particle count and achieving ISO compliance. Whether you’re designing a new cleanroom or updating an existing one, understanding airflow dynamics can help you avoid compliance issues, improve operational efficiency, and protect your products and processes

声明:

-文章转载自TECHNICAL,由爱泽工业翻译,如有侵权,请联系删除!

-如有偏颇,欢迎指正!

下一篇:了解液压球阀系统的功能(中英文)

沪公网安备31011002006738号

沪公网安备31011002006738号